Home / All / Floor Coating / Diamond Aggregate Hardened Floor System / Ultimate Defender for Emery Flooring: Lithium-based Concrete Sealer & Hardener. Boosts hardness by 300%, lifespan up to 30 years.

Ultimate Defender for Emery Flooring: Lithium-based Concrete Sealer & Hardener. Boosts hardness by 300%, lifespan up to 30 years.

Detail Information

Information

Lithium-based concrete sealer

Lithium-based concrete sealer is a sealing, dustproof, wear-resistant hardener. As a new-generation lithium-ion water-based product, it is colorless, odorless, non-toxic, and flame-retardant. By effectively penetrating 5–8mm, it reacts with free calcium/magnesium ions in concrete, forming a 3D network structure. This consolidates concrete components into a solid entity, creating a dust-free, dense whole. Capillary pores are permanently sealed, preventing dust emission while enhancing strength, density, and abrasion resistance.

Main components: Lithium silicate, etc.

Packaging: 20kg/barrel.

Barrel dimensions: height: 384mm, top diameter: 300mm, bottom diameter: 270mm, inner mouth diameter: 292mm.

Comparison of floor before and after using curing agent

Scope Of Application

Ideal for all venues requiring high strength, wear resistance, easy cleaning, and long-lasting aesthetics.

1. Industrial: Workshops, warehouses, heavy machinery zones, pharmaceutical/food plants (emphasizing cleanliness).

2. Commercial: Malls, shopping centers, parking garages, showrooms, 4S stores (emphasizing gloss).

3. Public facilities: Airports, stations, schools, hospital corridors (emphasizing durability & easy cleaning).

4. Others: Old floor renovation, sandy surface repair.

Product Features

1. Marble-like hardness, permanent dust/sand resistance, stain-proof & easy cleaning, lasting gloss, low maintenance costs.

2. Extreme hardness: Mohs hardness 8–9 (close to granite), 8x higher abrasion resistance than ordinary concrete. Withstands forklifts and heavy loads.

3. Permanent dustproofing: Seals pores completely, eliminating sanding/dusting for a clean environment.

4. Dense & impermeable: Blocks water, oil, and liquid stains effectively for easy cleaning.

5. Sealing & reinforcement: Enhances structural integrity, reduces cracking risk, extends lifespan (up to 30 years).

6. Enhanced gloss: With polishing, achieves marble-like luster (options: matte, semi-gloss, high-gloss).

7. Eco-friendly & safe: Non-toxic, odorless, ready for use after application.

8. Cost-effective: One-time investment, long-term benefits. Slashes cleaning, waxing, and renovation costs.

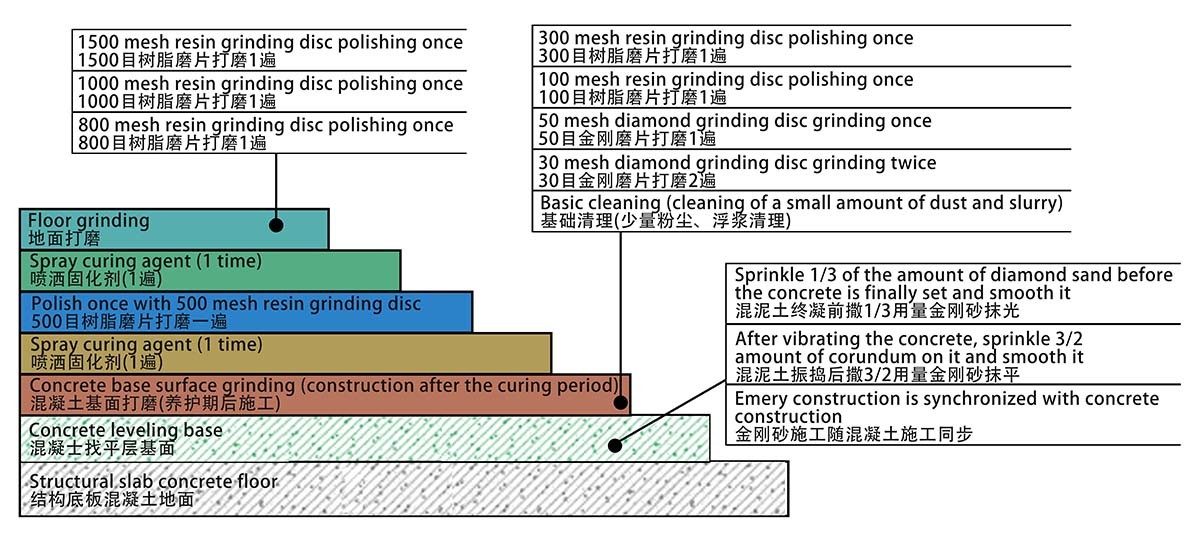

Construction Process

1. Substrate preparation (Critical): Clean, repair cracks, remove laitance/old coatings. Apply after 14-day curing when concrete strength ≥20MPa.

2. Coarse grinding: Use professional grinders to open concrete pores for penetration.

3. Apply sealer: Spray evenly on sun-dried surface. Soak for 2–3 hrs at 25°C until viscous and dry.

4. Fine grinding: Water-grind with 500-grit discs uniformly.

5. Apply sealer: Spray evenly on sun-dried surface. Soak for 2–3 hrs at 25°C until viscous and dry.

6. Fine Grinding and Polishing: Sequentially use resin abrasive discs of different grit sizes for fine grinding, superfine grinding, and polishing to gradually enhance the glossiness (until the desired effect is achieved).

7. Cleanup & curing: Clear debris, ready for use after 24–72 hrs curing.

Construction Section Diagram

Technical Specifications

| Performance Specifications of Lithium-based Concrete Sealer | |

| Parameter | Value |

| Appearance | Colorless transparent liquid |

Density | 1.10–1.20 g/cm³(20℃) |

pH value | 8.7–11.0 |

VOC content | 0 g/L |

Freezing point | -2°C to 0°C |

Flash point | Non-flammable |

Mohs hardness | 8 |

Penetration depth | 5–8 mm |

Dust emission rate | 0 |

Water absorption reduction | 90% |

Abrasion resistance ratio | 150% |

Flexural strength (ASTM C78-94) | 635PAI |

Impact resistance | Impact resistance increased by 12–15% |

Chemical resistance | Resists oil, acids, chlorides, and UV |

Drying time | Surface dry: 2–4 hrs (20°C); full cure: 7 days |

| Gloss level | Initial gloss at 24 hrs; significant enhancement in 30–90 days, no waxing needed |

Service life | Up to 30 years |

Flooring Performance Comparison

| Parameter Comparison: Lithium Hardener Floor vs. Ordinary Epoxy Floor | |||

Parameter | Lithium Hardener Floor | Ordinary Epoxy Floor | Performance Gap |

Mohs hardness | 8.0–9.0 | 1.0–4.0 | Lithium: 2–8x higher |

Abrasion resistance | Abrasion resistance ≥6.3 (ASTM D4060) | Abrasion resistance: Level 2–3 | Lithium: 2–3x higher |

Compressive strength increase | 40% increase at 28 days | Depends on substrate; intrinsic strength ≤30 MPa | Lithium significantly strengthens substrate |

Service life | 15–30 years (semi-permanent) | 3–5 years (requires refinishing) | Lithium: 3–10x longer |

Chemical resistance | Resists 60% H₂SO₄, saturated NaOH (no change in 3 days) | Resists 40% acids/alkalis (some products resist strong acids) | Lithium more stable |

| Penetration depth | 5–8 mm (permanently sealed pores) | Surface coating (0.2–0.5 mm) | Lithium penetrates substrate |

Dustproof activation time | Dust emission reduced to zero in 2 hrs | Effective after surface dry (~4 hrs) | Lithium faster |

VOC content | 0 g/L (water-based, eco-friendly) | Solvent-based: 200–300 g/L; Water-based: ≤50 g/L | Lithium absolutely eco-friendly |

Construction period | Single-day application, walkable in 24 hrs | 3–7 days (multi-layer coating + curing) | Lithium reduces construction time by 60% |

| Maintenance | Only water mopping needed | Requires wax maintenance | Lithium easier to maintain |

| Total cost (20-year) | Low (one-time application, no maintenance) | High (includes periodic refinishing costs) | Lithium saves >50% cost |

Project Case

Review

- Loading...

Please send your message to us

- *Name

- *Mobile Phone

- *Title

- *Content

Categories

- Architectural Coating

- Exterior Wall Paint

- Interior Wall Paint

- Formaldehyde Removal All-in-One Seaweed Mud Wall Paint

- Formaldehyde Removal 5-in-1 Diatomaceous Wall Coating

- Odorless 360 Antibacterial and Antiviral Wall Paint

- Odor-Free Mold-Proof Wall Paint

- Odorless 5-in-1 Diatomaceous Wall Paint

- Odorless 3-in-1 Diatomaceous Wall Paint

- Odorless All-in-One Diatomaceous Wall Paint

- Athletic Track Materials

- Plastic Sports Court Material

- Artificial Turf Material

- Floor Coating

- Epoxy Flooring Series

- Epoxy Flat Coating Flooring Material

- Epoxy Mortar Flat Coating Flooring Material

- Epoxy Self-leveling Flooring Materials

- Epoxy Anti-static Flat Coating Flooring Materials

- Epoxy Anti-static Self-leveling Flooring Materials

- Epoxy Colored Sand Flooring Material

- Solvent-free Epoxy Flooring Materials

- Epoxy Microbead Anti Slip Flooring Material

- Epoxy Super Wear-resistant Flooring Materials

- Epoxy Grinding Stone Flooring Material

- Epoxy Orange Peel Flooring Materials

- Epoxy Anti-corrosion Flooring Material

- Water-based Epoxy Flooring Series

- Polyurethane Flooring Series

- Water Permeable Flooring Series

- Diamond Aggregate Hardened Floor System

- Epoxy Flooring Series

Please send your message to us

- *Name

- *Mobile Phone

- *Title

- *Content