What is an Industrial Orange Peel Epoxy Topcoat for Parking Decks and Why is it a Solid Investment?

As experts in industrial flooring, we constantly seek solutions that combine durability, safety, and aesthetic appeal. Today, we're diving into the world of industrial orange peel epoxy topcoats for parking decks—a topic crucial for anyone managing commercial or industrial properties. We understand the demands placed on parking decks: heavy traffic, chemical spills, and constant wear. That's why choosing the right flooring solution is paramount. We believe an industrial orange peel epoxy topcoat is a solid investment, offering benefits that go beyond just surface protection. Let's explore why.

Key Takeaways

For facility managers and property owners needing a quick overview, here are the essential takeaways about industrial orange peel epoxy topcoats for parking decks:

-

Primary Function is Safety and Durability: The most critical feature of an orange peel epoxy finish is its textured surface, which is intentionally designed to provide superior slip resistance, even in wet or oily conditions. This is a crucial safety measure in a high-traffic environment like a parking deck, helping to prevent pedestrian slips and vehicle skidding. Beyond safety, the epoxy composition creates an incredibly durable and robust shield for the underlying concrete, protecting it from abrasion, impact, and chemical degradation.

-

Protects the Concrete Structure: An epoxy topcoat is a seamless, non-porous membrane that seals the concrete. This prevents water, oil, gasoline, de-icing salts, and other corrosive chemicals from penetrating the concrete slab. By stopping this ingress, the coating actively prevents the corrosion of the steel rebar within the concrete, which is a primary cause of structural failure, spalling, and costly repairs. It effectively extends the life of the entire parking structure.

-

Long-Term Financial Investment: While there is an upfront cost to professional installation, an orange peel epoxy topcoat delivers significant long-term savings. The cost of repairing structurally damaged concrete far exceeds the cost of preventive coating. Furthermore, the durability of the epoxy means fewer shutdowns for repairs, less need for frequent deep cleaning, and a service life that can span 10 to 20 years with proper maintenance. This high ROI makes it a sound financial decision for any commercial property.

-

Simplified Maintenance and Enhanced Aesthetics: Despite its textured finish, an orange peel epoxy surface is non-porous and easy to clean. Dirt, oil, and grime sit on top of the surface rather than soaking in, allowing for easy removal with standard cleaning equipment like auto scrubbers. This leads to lower labor costs and a consistently clean appearance. The uniform, professional finish, available in various colors, significantly enhances the facility's aesthetic, creating a brighter, safer, and more welcoming environment for tenants, customers, and employees. The ability to embed permanent line striping and safety markings further adds to its functionality.

-

Proper Installation is Non-Negotiable: The long-term success of an epoxy flooring system is almost entirely dependent on a professional installation process. This begins with meticulous surface preparation, including degreasing, diamond grinding or shot blasting to create a mechanical profile for adhesion, and thorough moisture testing. Any shortcuts in this phase will lead to coating failure, such as delamination or bubbling. The application itself requires expertise in mixing ratios, timing, and using the correct rollers to achieve the specified texture. Therefore, choosing a qualified and experienced contractor is as important as choosing the material itself.

Understanding Industrial Orange Peel Epoxy Topcoats for Parking Decks

When facility managers and property owners evaluate flooring solutions for parking structures, they are often confronted with a variety of technical terms and product options. One of the most effective and widely recommended solutions is the "industrial orange peel epoxy topcoat." But what does that term actually mean, and what makes it so suitable for the demanding environment of a parking deck? Understanding its composition and a unique texture is the first step in appreciating its value as a long-term asset.

What exactly is an "Orange Peel" Texture?

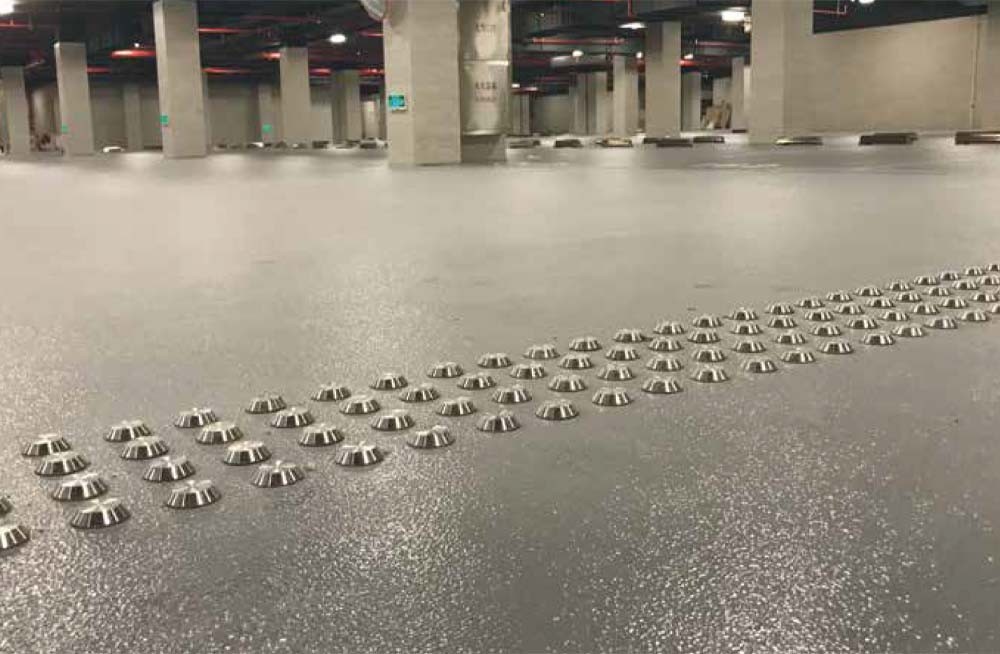

The term "orange peel" is a descriptive one, and in the context of industrial coatings, it refers to a specific, subtle, and highly functional surface texture. Unlike the smooth, glossy finish you might see in a showroom, this texture intentionally mimics the bumpy, dimpled skin of an orange. This texture is not a defect; rather, it is a deliberately created finish achieved during the application process by using specific rollers and application techniques. It’s a finely stippled surface that feels slightly rippled to the touch. The purpose of this texture is multifaceted, balancing aesthetics, cleanability, and, most importantly, safety and performance in a commercial or industrial setting.

Characteristics and Purpose of the Orange Peel Texture

The orange peel texture is engineered to deliver specific performance benefits that are critical for parking decks. Its characteristics are not merely for looks but are deeply rooted in functionality and safety.

-

Enhanced Slip Resistance: This is the primary and most critical purpose of the orange peel texture. A perfectly smooth, glassy floor can become extremely hazardous when wet or exposed to oil drips, creating a significant liability. The subtle, uniform dimples of an orange peel surface increase the floor's overall coefficient of friction. These micro-textures provide crucial grip for both shoes and tires, channeling away small amounts of water and reducing the risk of hydroplaning or slips and falls. This makes it an ideal choice for areas exposed to rain, snowmelt, and frequent washing.

-

Hiding Minor Substrate Imperfections: Concrete slabs, especially large ones found in parking decks, are never perfectly flawless. They often have minor trowel marks, patched areas, or slight unevenness. A high-gloss, smooth coating would highlight and magnify every tiny imperfection. The orange peel texture, however, has a light-diffusing effect. It breaks up the reflection of overhead lights, making minor flaws in the underlying concrete substrate much less noticeable and resulting in a more uniform and aesthetically pleasing final appearance.

-

Increased Durability and Scratch Concealment: The textured surface helps to mask small scratches and scuffs that are inevitable in a high-traffic area. On a smooth, glossy floor, every scratch from dragged equipment or tire grit is highly visible. The multi-faceted surface of an orange peel finish makes these minor abrasions blend in, maintaining the floor's fresh look for a longer period.

Composition of industrial orange peel epoxy topcoat for parking decks

An industrial orange peel epoxy topcoat is a high-performance, thermosetting polymer system. Understanding its composition helps clarify why it is so resilient and perfectly suited for the harsh conditions of a parking deck. It is typically a two-part system that, when mixed, undergoes a chemical reaction to cure into a hard, rigid, and durable plastic-like material.

The main components are:

| Component | Role and Function in the Coating System |

|---|---|

| Part A: Epoxy Resin | This is the backbone of the coating. The resin is typically based on bisphenol A or bisphenol F chemistry, which provides the fundamental properties of a highly durable, adhesive, and chemically resistant material. It is a clear, viscous liquid that, on its own, does not harden. The quality and purity of the resin are primary determinants of the final coating's performance, affecting its adhesion to the concrete, its chemical resistance, and its overall strength. |

| Part B: Hardener/Curing Agent | This is the reactive component. When mixed with the resin, it initiates a process called polymerization, or curing. Common hardeners include polyamines, amides, or cycloaliphatic amines. The choice of hardener dictates crucial properties like cure time, hardness, flexibility, and resistance to specific chemicals and UV light. For parking decks, manufacturers blend hardeners to create a balance of quick curing for a fast return to service and sufficient working time for a proper application over large areas. |

| Additives and Fillers | This is where the coating is fine-tuned for its specific purpose. Industrial-grade epoxies are not just resin and hardener; they are sophisticated formulas containing: • Pigments: To provide color, opacity, and improve UV resistance. Safety yellow, gray, and white are common for parking decks. • Flow and Leveling Agents: To ensure the coating spreads evenly before the texture is applied. • Thixotropic Agents: These are added to help the coating cling to the roller and create the "orange peel" stipple without sagging or leveling out completely smooth. • Reinforcing Fillers: Sometimes, microscopic fillers like quartz or aluminum oxide are added to the formula to dramatically increase abrasion resistance and compressive strength, preparing the floor for heavy, sustained traffic. |

The chemical reaction between the resin and the hardener creates strong cross-linked polymer chains. This results in a seamless, non-porous surface that is chemically bonded to the prepared concrete, forming a protective barrier that is far stronger and more resilient than a simple layer of paint.

The Unbeatable Benefits of Industrial Orange peel Epoxy Topcoats for Parking Decks

Choosing a flooring system for a parking deck is a decision with long-term consequences for a property's budget, safety record, and maintenance schedule. An industrial orange peel epoxy topcoat is not just a decorative finish; it's a strategic investment that delivers a host of benefits, making it one of the most reliable solutions for modern parking structures.

Enhanced Durability for High-Traffic Industrial Parking Decks

Parking decks are subjected to a relentless assault. This includes the constant movement of heavy vehicles, the abrasive action of tires turning, the impact of dropped items, and exposure to a range of damaging substances. An industrial epoxy topcoat is specifically engineered to withstand this abuse.

-

Abrasion and Wear Resistance: The tightly cross-linked polymer structure of cured epoxy is exceptionally resistant to abrasion. This means that the constant friction from car and truck tires, which can pulverize bare concrete over time, has a minimal effect on a coated surface. The textured finish further enhances this, as the wear is distributed across a varied surface rather than a flat plane. This prevents rutting and the formation of worn-out tire lanes, preserving the integrity and appearance of the floor for years.

-

Impact Strength: Industrial-grade epoxies possess high compressive strength, often exceeding 10,000 psi, which is several times stronger than standard concrete. This allows the floor to resist damage from impacts, such as a heavy tool being dropped or the pressure exerted by a car jack. This prevents the chipping, cracking, and spalling that commonly plague uncoated concrete surfaces, saving on costly patching and repairs.

-

Chemical Resistance: Parking decks are exposed to a cocktail of chemicals. Gasoline, motor oil, brake fluid, antifreeze, and, in colder climates, corrosive de-icing salts can all seep into porous concrete. These substances can stain the concrete and, more importantly, can break it down chemically and accelerate the corrosion of the steel rebar inside. An epoxy topcoat creates a seamless, non-porous barrier that is inert to these chemicals. Spills sit on the surface, waiting to be cleaned, rather than causing permanent damage to the structural slab.

Superior Slip Resistance: A Critical Feature for Industrial Parking Decks

In a public or commercial space, safety is paramount. Slips, trips, and falls are a leading cause of injuries and a major source of liability for property owners. Parking decks, which are frequently exposed to rain, snow, and fluid leaks, are particularly high-risk areas. The Orange Peel Texture Epoxy Flooring Paint is specifically designed to mitigate this risk.

The intentionally created texture is the key. Unlike a smooth, flat surface where a layer of water can create a direct hydroplaning hazard, the "hills and valleys" of the orange peel finish perform two functions:

- They increase the surface area for contact, providing more points of grip for shoe soles and vehicle tires.

- They create small channels for water to disperse, preventing a continuous film of liquid from forming between the surface and the person or tire.

This results in a significantly higher static coefficient of friction (SCOF), especially in wet conditions. This built-in safety feature is active 24/7, reducing the risk of accidents for pedestrians walking to and from their vehicles and providing better traction for cars, especially on ramps and turning areas.

Long-Term Cost Savings and Longevity of Industrial Orange Peel Epoxy Topcoats

The initial investment in a professionally installed epoxy system can seem higher than simply painting or leaving the concrete bare. However, a comprehensive lifecycle cost analysis reveals it to be a far more economical choice over the long term.

-

Prevention of Major Structural Repairs: The single greatest cost associated with parking deck maintenance is concrete repair. When water and salts penetrate the concrete and corrode the rebar, it leads to spalling (large chunks of concrete breaking away) and structural degradation. Repairing this damage is invasive, expensive, and requires shutting down sections of the deck. An epoxy topcoat acts as a waterproofing membrane, preventing this corrosion cycle from ever starting. This preventive measure saves enormous amounts of money over the life of the structure.

-

Reduced Maintenance Costs: Uncoated concrete is porous and generates its own dust. It stains easily and is difficult to clean, often requiring power washing. A non-porous epoxy surface is far easier and cheaper to maintain. Daily sweeping and periodic cleaning with a standard auto scrubber are usually all that is needed to keep the deck looking pristine. This reduces labor hours, water usage, and the need for harsh cleaning chemicals.

-

Extended Lifespan: A properly installed and maintained industrial epoxy floor can last anywhere from 10 to 20+ years, depending on the thickness, quality of the material, and the level of traffic. Compared to paint, which may need to be reapplied every 1-3 years, the longevity of epoxy means fewer disruptions and a much lower total cost of ownership.

Aesthetic Appeal and Ease of Maintenance for Industrial Parking Decks

A parking deck is often the first and last impression a visitor has of a building. A dark, stained, and dusty parking garage can feel unsafe and unwelcoming. An orange peel epoxy topcoat can completely transform the space.

-

Brighter, Safer Environment: Epoxy coatings are available in a wide range of standard and custom colors. Lighter colors like gray, beige, or white can significantly increase the brightness and reflectivity of a parking garage. This improves visibility, enhances the effectiveness of existing lighting, and creates a feeling of safety and cleanliness.

-

Professional, Uniform Appearance: The seamless finish provides a clean, modern, and professional aesthetic. Furthermore, line striping, directional arrows, logos, and pedestrian walkways can be embedded into the epoxy system, creating permanent markings that will not wear away like paint. This contributes to better organization, traffic flow, and safety.

-

Effortless Cleaning: As mentioned, the non-porous nature of epoxy is a game-changer for maintenance. Because oil, dirt, and salt crystals cannot penetrate the surface, they are easily swept or washed away. This means a cleaner facility with less effort, projecting a positive image for the property.

Application and Installation Considerations for Industrial Orange Peel Epoxy Topcoats on Parking Decks

The exceptional performance and longevity of an industrial orange peel epoxy topcoat are not inherent to the product in the can; they are the result of a meticulous and professional installation process. The "system" of preparation and application is just as critical as the chemical composition of the epoxy itself. For property managers, understanding these steps is key to ensuring a successful, long-lasting investment and to properly vetting a qualified contractor.

Preparing Your Parking Deck for an Industrial Orange Peel Epoxy Topcoat

Industry experts unanimously agree that surface preparation is the single most important factor in the success of any industrial coating system. It is estimated that up to 80% of all coating failures are due to inadequate or improper surface preparation. A pristine, properly profiled concrete substrate is essential for the epoxy to achieve a permanent chemical and mechanical bond. Skipping or rushing any of these steps will almost certainly lead to premature failure, such as peeling, bubbling, or chipping.

The key stages of surface preparation include:

-

Thorough Cleaning and Degreasing: The surface must be completely free of any contaminants. This includes oil, grease, hydraulic fluid, tire rubber, dirt, and existing, poorly-bonded paint or sealers. This is typically accomplished using industrial-grade degreasers, pressure washing, and steam cleaning.

-

Concrete Repair: All existing damage to the concrete must be professionally repaired. This involves:

- Crack Repair: Dynamic (moving) cracks and static (non-moving) cracks are routed and filled with flexible epoxy or polyurea crack fillers.

- Spall and Chip Repair: Any areas is broken or chipped are squared off and patched with a high-strength epoxy mortar. The goal is to create a solid, stable, and relatively smooth surface before the coating process begins.

-

Mechanical Surface Profiling: This is the most critical step. For the epoxy to "grip" the floor, the smooth, hard surface of the concrete must be opened up to create a texture, known as a Concrete Surface Profile (CSP). A CSP of 2-3, similar in texture to 60-grit sandpaper, is typically required. This cannot be achieved with acid etching, which is an unreliable and outdated method. The proper methods are:

- Diamond Grinding: Machines with rotating diamond-abrasive heads grind away the top layer of concrete, removing contaminants and creating the ideal profile. This is the most common method for parking decks.

- Shot Blasting: Tiny steel beads are propelled at high velocity at the concrete surface, abrading the top layer. This method is very efficient for large, open areas. All grinding and blasting must be done with equipment attached to powerful industrial vacuums to control dust.

-

Moisture Testing: Concrete is porous and can hold significant amounts of moisture. If an epoxy coating is applied to a slab with high moisture vapor transmission (MVT), the hydrostatic pressure can push the coating off from below, causing widespread blistering and failure. Professionals use standardized tests, such as the Calcium Chloride Test (ASTM F1869) or the In-Situ Relative Humidity Test (ASTM F2170), to measure the MVT rate. If moisture levels are too high, a special moisture-vapor-barrier epoxy primer must be installed first.

The Application Process of Industrial Orange Peel Epoxy Topcoats

Once the substrate has been perfectly prepared, the application of the epoxy system can begin. This is a time-sensitive process that must be carried out by a skilled crew in a controlled environment.

-

Priming the Concrete: The first coat to be applied is an epoxy primer. The primer is a thinner, lower-viscosity epoxy設計 to penetrate deep into the pores of the prepared concrete. This serves two main purposes: it seals the concrete to prevent outgassing (which causes bubbles in the topcoat) and it creates a tenacious bond deep within the slab, acting as an anchor for the subsequent coats.

-

Applying the Build/Body Coat: After the primer has partially cured (reached its "re-coat window"), the main body coat of pigmented epoxy is applied. This is typically a 100% solids epoxy that is squeegeed and back-rolled across the surface to a specific thickness. This layer provides the bulk of the color, chemical resistance, and impact strength of the system.

-

Creating the Orange Peel Texture: The final step is the application of the topcoat. While the body coat is still tacky, or after it has cured and been sanded, the orange peel epoxy topcoat is applied. This is done using a specific type of roller with a certain nap thickness. The applicator uses a precise technique of rolling and "tipping off" the surface to create the uniform, stippled texture. The viscosity and thixotropic properties of the topcoat are designed to hold this texture as it cures, rather than leveling out into a smooth film.

-

Curing and Return to Service: The epoxy system must be allowed to cure undisturbed. Curing times are dependent on the specific product, temperature, and humidity.

- Light Foot Traffic: Typically possible within 24 hours.

- Heavy Traffic/Vehicles: Usually requires 3 to 7 days for the epoxy to achieve its full hardness and chemical resistance. Opening the deck to traffic too early can cause permanent damage to the finish.

Frequently Asked Questions (FAQ)

1. How long does an industrial orange peel epoxy topcoat last on a parking deck?

The lifespan of a professionally installed industrial epoxy system is one of its most significant advantages. With proper maintenance, you can generally expect a service life of 10 to 20 years. However, this range depends heavily on several factors: the quality of the materials used, the thickness of the applied system, the thoroughness of the initial surface preparation, the volume and type of traffic, and the consistency of the cleaning regimen. In a very high-traffic commercial deck, the lifespan might be closer to the 10-12 year mark, whereas in a lower-traffic condominium garage, it could easily exceed 15-20 years. The key takeaway is that it is a long-term solution, unlike paint, which may require re-application every 2-3 years.

2. Is the orange peel texture difficult to clean?

This is a common misconception. While the surface is textured, it is still completely non-porous and seamless. Dirt, oil, and other contaminants cannot penetrate the surface. Unlike rough, porous concrete, which traps grime, the epoxy surface allows debris to be easily removed. For routine cleaning, a simple sweep with a commercial dust mop is effective. For more thorough cleaning, an auto scrubber with a non-abrasive pad and a neutral pH cleaning solution is ideal. The texture does not "grab" dirt in a way that makes it difficult to release, making it remarkably easy to maintain a high level of cleanliness.

3. all Can this type of coating be applied over my existing old coating?

The answer is a conditional "maybe." It is never recommended to apply a new epoxy system over an old, failing coating. If the existing paint or coating is peeling, chipping, or has lost its adhesion to the concrete, it must be completely removed via diamond grinding or shot blasting. Applying a new, strong coating over a weak, poorly-bonded layer is a recipe for failure; the new coating will simply peel off, taking the old one with it. However, if a professionally installed epoxy floor is still well-bonded but is simply worn or needs a color change, it can often be "screened and re-coated." This involves mechanically abrading (sanding) the surface of the existing epoxy to create a profile, and then applying a new topcoat. A qualified contractor must perform adhesion tests to determine if the existing coating is sound enough to be coated over.

4. How long will my parking deck be out of service for the installation?

The project duration depends on the size of the area, the condition of the existing concrete, and ambient environmental conditions (temperature and humidity). A typical project can be broken down as follows:

- Surface Preparation: 1-3 days. This is the most labor-intensive part and includes grinding and any necessary repairs.

- Application: 2-3 days. This includes a primer coat, a body coat, and the textured topcoat, with specific curing times required between each coat.

- Final Cure: 3-7 days. While the floor may be open to light foot traffic in 24 hours, it needs to fully cure and harden before it can withstand the weight and friction of vehicle traffic. Therefore, a facility manager should plan for the area to be completely out of service for approximately 5 to 7 days from the start of the project. For very large projects, work can be phased to keep portions of the deck operational.

5. Is the application process very smelly or dangerous for building occupants?

Professional-grade industrial epoxies have evolved significantly. While traditional solvent-based epoxies had very high levels of Volatile Organic Compounds (VOCs) and produced strong, noxious odors, the industry standard today is 100% solids epoxy. These formulations have zero or very low VOCs. During application, there is a distinct "amine" odor, which is often described as smelling similar to ammonia, but it is not hazardous in a well-ventilated area and dissipates as the coating cures. A professional contractor will always ensure adequate ventilation and will section off a work area to prevent odors from migrating into occupied spaces of the building. For tenants and visitors, the process is safe and minimally disruptive.

We've seen that an industrial orange peel epoxy topcoat for parking decks isn't just about covering concrete; it's about making a strategic, long-term investment in safety, durability, and cost-effectiveness. This advanced flooring system addresses the most significant challenges faced by parking structures, from relentless traffic and chemical spills to the critical need for pedestrian safety. By forming a seamless, tough, and slip-resistant barrier, it protects the building's structural integrity while simultaneously enhancing its aesthetic appeal.

When you consider the enhanced safety from its textured surface, the extended lifespan of the concrete slab it protects, and the drastically reduced maintenance demands, it becomes clear: an industrial orange peel epoxy topcoat for your parking deck is a decision that truly pays off. It is a proactive measure that prevents costly future repairs, limits liability, and projects an image of quality and care for your property. We encourage you to share this article with colleagues and consider this high-performance solution for your next project.